SA Mining

Pandemic Rattles Global Markets

By Nelendhre Moodley

The world has been shaken, markets have been rattled and companies have been rolling off the bandwagon by the thousands. The COVID-19 pandemic continues to leave death and destruction in its wake, forcing everyone to revaluate their lives and business strategies.

2021 is certainly going to be a year of reinvention. But for companies whose foundations are built on innovation and technology, with an eye to future sustainability, the process will be less painful.

For Gauteng-based Brelko, 2020 has been a tough year. However investments made over the years related to sustainability, including those associated with diversity, product innovation and patents, employee training and local manufacturing capabilities, have enabled the company to ride out the COVID-19 wave as best as possible.

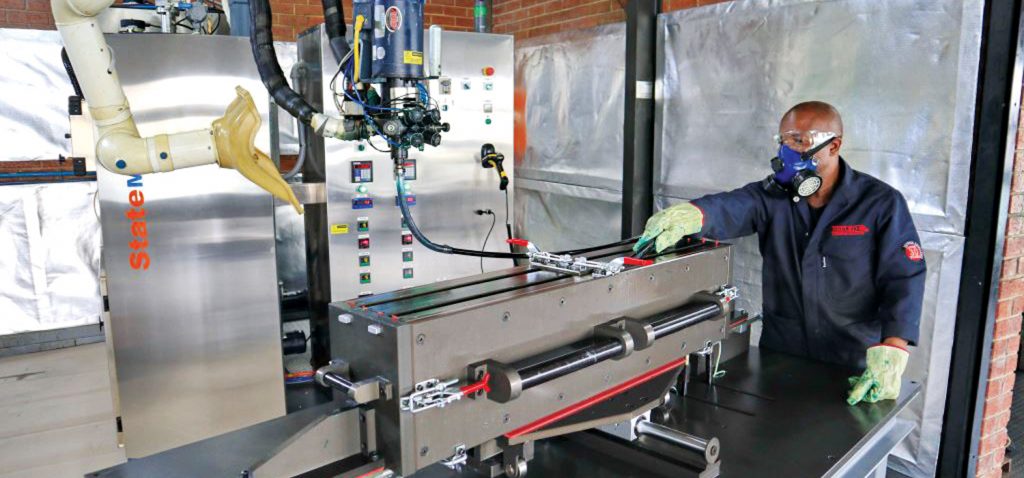

Brelko is a Level 1 B-BBEE-accredited company, supplying polyurethane rollers, belt scrapers, Keyskirt chute sealing systems, belt centralising systems and polyurethane hi-impact systems across a number of sectors, predominantly the mining sector.

Driving the sustainability agenda

Sustainability is described as the ability to exist constantly; which means always reinvesting to keep a business relevant for the future.

“Brelko has a robust sustainability agenda, identifying and progressing about 20 top priority areas at any given time. This helps us to improve efficiency, productivity and ultimately profitability,” says MD Kenny Padayachee.

The company was established 33 years ago as a producer of conveyor belt cleaning equipment, but today it has grown to the point where it supports the entire conveyor belt needs in terms of spillage.

“We reinvest in the company with a view to add value across the larger supply chain. Over the years we have honed our skills to become a totally local manufacturer; producing our own designs and 3D drawings to manufacture, install and maintain our products. In fact, over the past five years we started designing and manufacturing the moulds that produce our range of products inhouse,” says Padayachee.

Key developments in the spotlight include expanding the factory to accommodate its ever-growing needs, completing construction of the company’s warehouse and stocking it, continuously upgrading employee skills sets and improving software systems, among others.

Brelko’s skills development and training programmes work to align their workforce with the latest technological developments.

“Where accountants see employees as liabilities and expenses, we at Brelko see our people as assets, and certainly as an appreciating asset, as they continually add value to the company through productivity. When you invest in people you bring out the best in them which ultimately translates to increased returns,” says Padayachee.

Given its niche market product range, seeking out new clients and markets and diversifying its geographical footprint beyond Africa is a strategic focus area for the equipment manufacturer.

“We have an ear to the ground, constantly pursuing new clients. We put ourselves out there to find these new clients, whether it is in Africa, Saudi Arabia, Mexico or the USA. In fact, our endeavours have resulted in Brelko being present in 40 countries across the globe. Essentially, we believe in our product and its capabilities and understand the benefits that our premium-quality products can deliver to clients, especially in terms of improved productivity and longevity. And so we seek out companies that we believe will benefit from adopting our products.”

2021 – working within the confines of a new normal

The good news is that a new COVID-19 vaccine has been developed by Pfizer, an American multinational pharmaceutical corporation, and German company BioNTech, which is considered to be 90% effective. However it may be a while yet before it reaches the continent, so it will be business as (un)usual for a bit longer.

Nevertheless, the conveyor belt cleaning equipment manufacturer will be steaming ahead on its earmarked projects, which includes rolling out and completing Phase 4 of its solar project.

In a bid to reduce its reliance on Eskom’s unreliable power supply, in 2018 Brelko took a decision to roll out phase one and phase two of its solar power project.

By November 2020, the company completed phase 3 which delivered 500KW of power bringing the total off-grid power supply to 2 000KW.

Coupled with an anticipated completion of phase 4 in 2021, which is set to deliver a further 1 000KW, the company will also acquire batteries to store up excess power.

Once complete, the solar power plant will produce 3 000KW per day, allowing Brelko to be off-grid and independent of the local power producer. This will ensure a constant supply of power to run the factory on a 24-hour basis.

Further to this, the company is scheduled to complete construction of its massive 2 500m² warehouse. The three-level custom-designed warehouse will be equipped with a hydraulic goods lift for increased efficiency.

“The years of investment to improve productivity, efficiency and ensure future sustainability have paid off. During a challenging time like this, we have been able to cope easily,” says Padayachee.

Sign-up and receive the Business Media MAGS newsletter OR SA Mining newsletter straight to your inbox.

Sign-up and receive the Business Media MAGS newsletter OR SA Mining newsletter straight to your inbox.