SA Mining

Bang For Your Buck

By Nelendhre Moodley

COVID-19 has been associated with many negatives. However some positives have also emerged from the pandemic, including an increased focus on innovation and technology. SA Mining recently spoke to Bell Equipment South Africa’s CEO Leon Goosen about some of the latest innovative developments under way at the company.

What has been the impact of COVID-19 on the equipment market and Bell Equipment in particular?

COVID-19 has created a unique operating environment for everyone, not just the equipment market. We’ve had to change the way we operate to ensure that we meet government regulations and our own protocols in terms of the virus.

While Bell has not been immune to the impact of COVID-19 on the business and our people, we are grateful for the low rate of infection among our employees. We largely attribute this to the timely and stringent protection measures that were implemented across all operations and adherence by our employees and stakeholders.

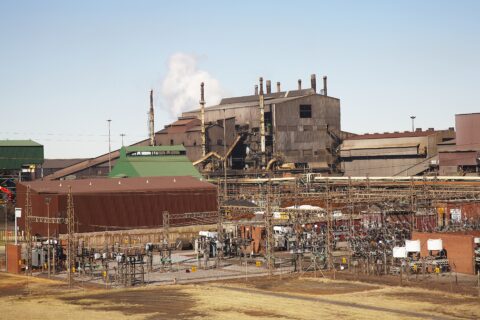

As a supplier of essential services to agriculture and mining, particularly coal mines supplying Eskom, our business was able to continue with a higher degree of normality than many other industries.

We were also fortunate that a large portion of our workforce was able to work remotely during the initial lockdown, which helped to lessen the impact on the business. There were inevitably some supplier and supply chain disruptions, but these have mostly been addressed and we continue to monitor our supply chains from Europe and the US where there are signs of an increasing infection rate.

Have there been any positives to come out of the pandemic for equipment manufacturers?

For Bell Equipment, one of the greatest positives has been the way in which our employees have pulled together to make the most of the difficult trading conditions and the challenge of the virus to ensure that our customers continue to receive a quality service during this trying period.

From a customer perspective there is still nothing better than face-to-face contact, but the forced integration of technology has taken us forward in leaps and bounds and helped to streamline processes. Previously we would fly to Johannesburg for meetings, but the pandemic has proven to us that remote working and cooperation is feasible and effective by using the available technology to our advantage.

Although not a result of the pandemic, there has been a gathering of momentum for autonomous developments and it has shown us how close to the market we are in this regard. We thought that autonomous development was still in the early adopter stage, but during COVID-19 we’ve seen an increase in market awareness and real enquiries.

What is Bell Equipment’s outlook for the equipment market in 2021? What will be the driving factors?

During 2021 we will be looking for growth from a relatively low base and we’re not expecting any fireworks. We are cautiously optimistic that governments will be spending money on economic recovery after the pandemic and infrastructure development is a catalyst for economic development. After several dire years for the construction industry in South Africa we are hoping to see some real growth in this sector and an increased demand for equipment.

What new developments, including product launches, does Bell Equipment have scheduled for 2021?

We’re currently in the testing phase of our new-generation low-profile articulated dump trucks for underground mining, which we are excited about. There are two models, the Bell B30L and the B35L, and both feature a new left-side mount cab and include all our standard features for safety, productivity and machine protection.

This includes keyless start, hill assist, speed control, bin tip prevention, auto park application (APA) and turbo spin protection to protect the engine. Onboard weighing is now standard on these trucks and Bell Equipment’s proprietary fleet management software, Fleetm@tic®, enables machine owners access to daily production figures.

In addition to delivering on our lowest cost per tonne philosophy, these trucks also have an “autonomous ready” platform that is easily configurable for remote operation either by a handheld remote control or a more sophisticated autonomous control centre.

In March 2020, before the hard lockdown, we were able to showcase our new Bell Tracked Carrier at ConExpo in Las Vegas, US, which is a niche solution for soft underfoot conditions. The machine will be manufactured in our Richards Bay facility and is available as either a seven-tonne or 11-tonne truck and can be fitted with either a dump body or a flat deck.

We are excited about putting units on the ground in the United States next year and seeing where this development leads in terms of other potential new markets.

From an innovation and technology point of view, how are customer requirements shaping the industry?

Our strength in the past has been listening to our customers, which has got us to where we are today. No one knows the application, the developments and innovations that are happening in the industries where our machines are operating better than our customers. Listening to them to understand the industry requirements is the best way to stay on top of what innovation and technology is needed.

When customers consider an original equipment manufacturer (OEM), there are two main elements: the cost per tonne that they get from a machine and the relationship they have with the OEM. The relationship element is becoming more and more challenging due to factors like institutional buying, so we need to constantly push the boundaries to make sure the cost per tonne element is there.

To provide lowest cost per tonne solutions throughout a machine’s lifecycle, Bell is always looking at ways to optimise the cost of a machine and the maintenance thereof, while at the same time building on quality, reliability and durability to deliver residual value.

How is Bell Equipment aligned with technology and innovative developments?

Our philosophy of listening to our customers has seen us pioneering various technologies and innovative developments. We were first to market with a telematic fleet management solution on our articulated dump trucks, known as Fleetm@tic®.

We were the first manufacturer to offer an onboard weighing solution, which is standard on our trucks and works with the Fleetm@tic® technology. To improve the accuracy of our onboard weighing, we fitted inclinometers and saw an opportunity to use this technology to also increase the truck’s safety functions with i-Tip that automates the speed of the tip and Tip Safe that prevents tipping at unsafe angles. In this way we’ve stayed at the forefront of ADT technology.

In terms of speed controls, speed limits, slope control and geofencing, we can now limit the speed in specific areas of a site based on the incline of a slope. If an area is steeper than a certain percentage downhill then the truck will automatically brake through the retarder and reduce the speed so that the truck travels at a safe speed on that slope, which has massive benefits in terms of safety.

This is set within the central display unit in the cab and can be set up according to whether the truck is laden or unladen, giving almost endless control of the machine.

To comply with PDS (Pedestrian Detection System) regulations we needed electronic control of certain functions, for example brakes, to create electronic control within the truck. Once we had achieved that, it was easier to expand the electronic control to steering and accelerating.

This then led to creating an interface for external companies to test how their software controls affect our machine so that they can calibrate their controls to get the correct response from our truck. Using open-source technology allows customers to choose any service provider so that they can have full integration on their site.

We have trucks working on an autonomous test site in a quarry in Europe where they are performing well and our new low-profile trucks for underground mining also have an “autonomous ready” platform.

Sign-up and receive the Business Media MAGS newsletter OR SA Mining newsletter straight to your inbox.

Sign-up and receive the Business Media MAGS newsletter OR SA Mining newsletter straight to your inbox.