SA Mining

Menar Diversifies

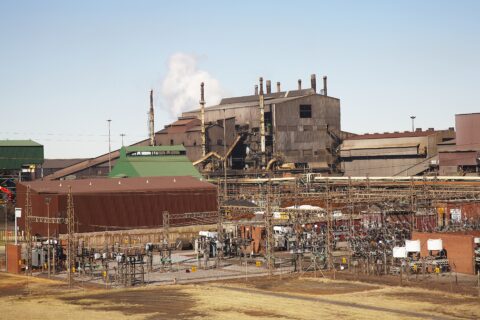

As part of its diversification strategy, mining investment company Menar is at an advanced stage of developing a test case through its East Manganese operation in the Northern Cape.

The Hotazel operation has reached first Manganese ore at the beginning of September 2021 and will soon be ramping up to nameplate capacity of over 30 000 tonnes a month of ore.

SA Mining recently caught up with chief operating officer of the East Manganese project, Kobus Rothmann, to chat about the project development and its environmental management strategy.

According to Rothmann, Menar is carrying out concurrent rehabilitation of mining areas as it progresses the project.

“To date, the Menar Mining Services workshop has been completed, as well as the ablution facilities, the run-of-mine pad, the processing plant and the pollution control dam, ramps and mine roads. The onsite laboratory is in the final stages of construction,” he says.

Given that the East Manganese mine is situated in a water-scarce area, the water is being sourced from the Sedibeng pipeline. Strict compliance with environmentally sound water-use methods will be considered part of the project’s success.

“The mine’s dry crushing and screening plant has been commissioned, which will improve the mine’s water-use efficiency. East Manganese uses a closed water reticulation system, which ensures that no contaminated water is released from the site,” Rothmann says.

“The water is channelled and collected in pollution control dams. This water is in turn used for dust suppression within the mine’s boundary and in the processing plant. The project is committed to adhering to all environmental regulations.”

Rothmann says potable water is used only for consumption by the mine’s employees.

Although the miner has considered the use of solar energy to power the mine’s infrastructure, such as weighbridge and office operations, the idea was considered not viable due to the limited life of the mine’s three years.

“We would have liked to use solar, but unfortunately it would not have been economically efficient because of the short lifespan of the mine,” says Rothmann.

Thus all electricity needs are met through generators.

East Manganese is contributing to the economic development of the small mining town, as it was projected to create between 70 and 80 direct new jobs at peak production.

“If we multiply this figure by 10 (which is the average number of people who are dependent on a single salary earner in South Africa), then in essence 700 to 800 people will directly benefit from this project. The mine currently has 80 employees, mainly recruited from local communities,” Rothmann says.

“In addition, indirect economic benefits of the operation, even though not quantifiable, will also be far-reaching. We have since inception provided opportunities to local companies with abilities to deliver cost-effectively. We are engaging with local stakeholders, including the local municipality, to finalise and execute our Social and Labour Plan as required by legislation.”

Sign-up and receive the Business Media MAGS newsletter OR SA Mining newsletter straight to your inbox.

Sign-up and receive the Business Media MAGS newsletter OR SA Mining newsletter straight to your inbox.