SA Mining

Air-Rated: Atlas Copco Digs Deep

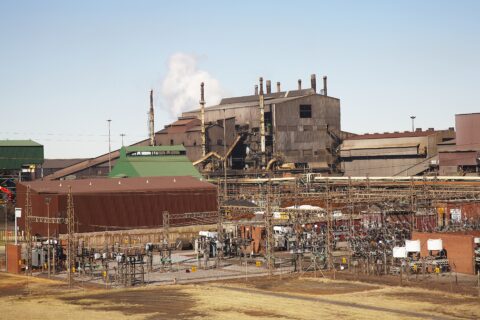

With mining houses largely holding a conservative view in terms of exploration spend – this on the back of challenging economic conditions – innovative product manufacturers such as Atlas Copco have developed sophisticated fuel-efficient equipment and diversified their product portfolio to compete in new markets, David Stanford, business line manager, portable products, Atlas Copco Power Technique tells SA Mining.

According to Stanford, although the sentiments were of improved exploration spend as outlined by the S&P Global Market Intelligence World Exploration Trends 2018 report, which forecasted the global exploration budget to increase in 2019, the exploration spend had yet to filter down to sub-Saharan Africa.

The report noted that global exploration spend was expected to increase in 2019 “for a third consecutive year but by a smaller amount of 5% to 10%”.

Stanford explains that drilling and exploration spend are closely linked. When companies are cash-flush they have available funds to invest in exploration; however during tough times exploration spend is one of the first casualties.

“This year, and in particular this quarter, has been extremely challenging especially from the compressor business unit point of view; but we are hopeful that the slight uptick experienced in July will continue for the remainder of the year.”

Driving the green agenda

The Southern African market remains suspended between premium efficiency products and basic fit-for-purpose products, explains Stanford.

“The push for lower carbon emissions remains a key driver in the market with the US and Europe leading the way in the rollout of Tier 4 diesel engines and an eye to the next level of curbing emissions.”

In line with the drive for energy-efficient products, Atlas Copco offers mechanical electronics benefits at Tier 3 level which are simple to use and therefore well suited to the Southern African market.

“We have a range of products that meet the need for basic drilling such as the XRV1200 mechanical compressor used in water-well drilling, exploration and blast-hole drilling applications as well as more sophisticated products such as the Pressure Adjusted through Cognitive Electronics (PACE) technology and the DrillAirXpert performance management system. Our drill air product range is no different to European models when it comes to flexibility; the difference lay in the engine tier rating. Thus less regulated countries benefit from receiving top product ranges aligned to a lower carbon footprint,” says Stanford.

Highlighting the recently promulgated carbon tax, he states that it is a driver for change and will work towards improving industrial operations. “We embrace it and will adapt to meet the changing requirements.”

Manufacturing innovative drilling equipment

Atlas Copco’s philosophy of developing innovative solutions is aligned with meeting the needs of the cost-conscious customer.

“Our compressors, which include groundbreaking technologies such as PACE as well as the DrillAirXpert performance management system, are defined by enhanced manoeuvrability, fuel efficiency, increased machine lifespan, low maintenance and extended service intervals. Our products are designed around pressure and flow and are aimed at offering premium quality compressed air. This allows the DrillAir range, which encompasses the XAVS 1000, V900, X1300, V1200 and Y1300, to achieve maximum air flow at any pressure setting,” notes Stanford.

Atlas Copco’s DrillAir compressor range offers multiple pressures from a single machine and thus eliminates the need for multiple machines. On its PACE technology Atlas Copco is able to offer pressure settings of 8-10bar and 12-14bar on a single product.

“The customer is able to cover two applications with one machine and rental companies supplying a fleet of compressors achieve increased versatility and flexibility and significant cost savings.

“While it is well known that the higher the pressure the deeper one is able to drill, it is also true that the higher the pressure the faster one drills. Therefore higher-pressure machines also deliver increased productivity. Apart from lower fuel consumption and increased drilling capability, clients benefit from drilling more holes cost-effectively.”

Boasting a compact footprint, the machines are transported easily between drilling sites.

According to product manager Zandra van der Westhuizen, a further product benefit is the associated ease of maintenance, which includes among others a standardised service kit. “When a customer orders a service kit, it comes complete with the required spares and guidelines. Atlas Copco also offers online shopping.”

The DrillAir range is ideal for geothermal drilling and construction, blast hole drilling and exploration (mining) and pipeline applications, well services as well as aerated drilling (oil and gas).

Sign-up and receive the Business Media MAGS newsletter OR SA Mining newsletter straight to your inbox.

Sign-up and receive the Business Media MAGS newsletter OR SA Mining newsletter straight to your inbox.