BD Manufacturing

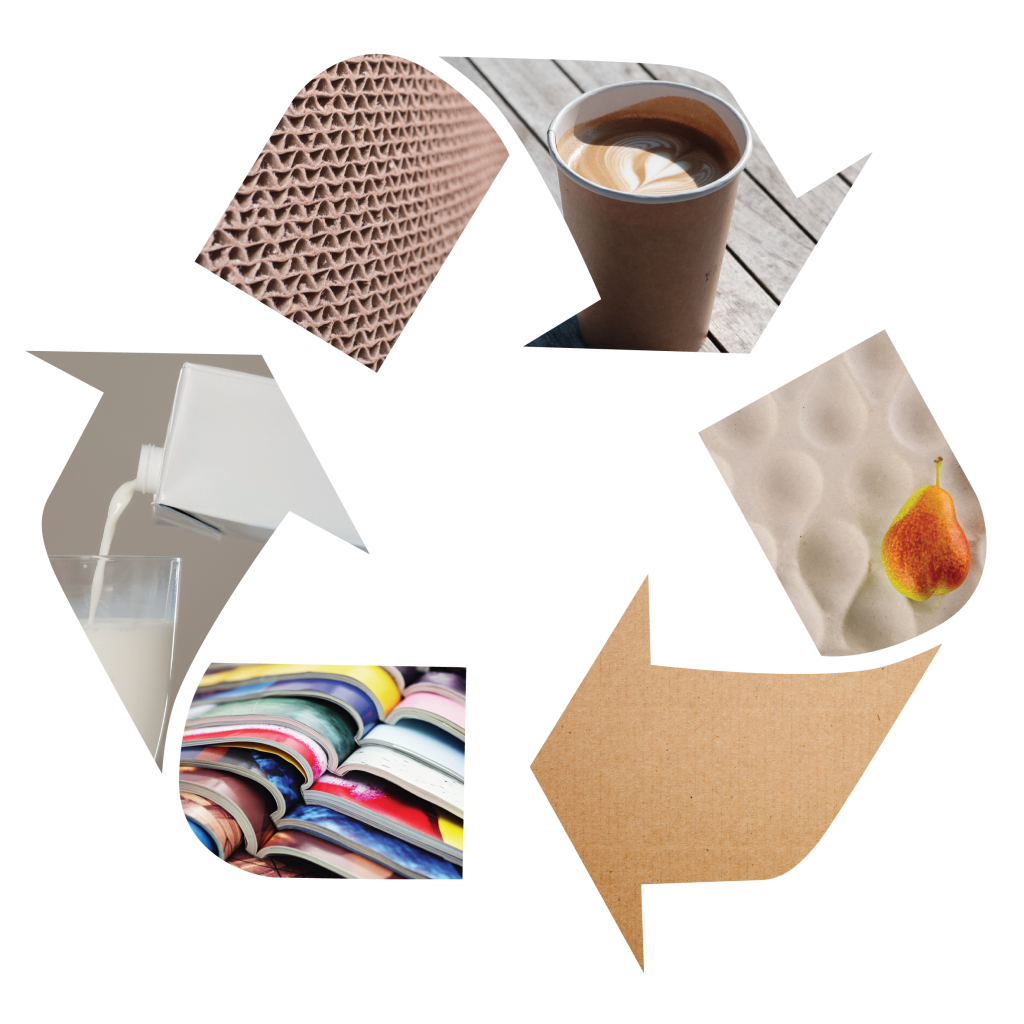

Paper And Packaging: Preserving The Forest

The South African forestry industry has a staggering 840 million trees planted over 693 000 hectares for pulp and paper production. In South Africa, paper is produced from sustained forestry, where trees are grown in rotation with only six per cent of the total area harvested each year. Felled areas are replanted, and there are thousands of hectares of trees of different ages growing all the time. Farmed trees are also not irrigated, drawing their water from rainfall and groundwater sources.

Environmental stewardship

“We often say that trees don’t grow from the ground; they grow from the air, absorbing carbon dioxide, storing the carbon and releasing the oxygen,” says Jane Molony, executive director of the Paper Manufacturers Association of South Africa (PAMSA). “This carbon remains locked up in the fibre, through the life cycle of a paper product. This is why recycling is so important: it keeps the carbon locked up for longer.” The sector prides itself on environmental stewardship, with a focus on carbon sequestration, water-efficiency, the use of renewable biomass-based energy and steam recovery. Molony says that the trees grown by the industry are grown especially for fibre (pulp and paper) and timber (sawmilling). “Eighty per cent of our country’s plantations are Forest Stewardship Council certified. We are proud of the fact that 25 per cent of the land allocated to plantations is set aside for biodiversity, and that some of the best-managed wetlands are owned by forest and forest product companies.”

All paper made in South Africa comes from either virgin fibre of sustainably managed plantations or recycled paper fibre, or a combination of the two. Some mills use bagasse, the waste from sugarcane processing. “We can meet our domestic needs for A4 copier paper, newsprint, toilet tissue and most packaging grades,” says Molony. “There are certain grades that are not made locally any more such as coated stocks for magazines, brochures and high-end printing. With the decline in demand, the mills or paper machines producing these grades closed down and, where possible, changed to produce packaging grades of paper.”

The product that keeps on giving

More than 12 million tonnes of waste paper and packaging have been recovered in SA over the past decade, diverting it from landfills.

In 2019, South Africa collected 68.5 per cent of recoverable paper and packaging, down from 71.7 per cent in 2018. “This is largely due to the nature of a waste economy,” explains Paper Manufacturers Association of South Africa executive director Jane Molony. “Products are not produced especially for recycling; they are a byproduct of a healthy consumer demand and economy. The industry was able to use 90 per cent of its recovered waste paper locally by recycling it, with the balance exported, even though the local industry can generally use all the waste paper. The exchange rate encourages the export of waste paper.”

Molony says that much research is being undertaken to improve the recovery and recyclability of multilayer papers like beverage cartons and paper cups, which would improve access to more fibre. “This fibre is also ‘virgin’ and thus could provide a recycling mill with consistent raw material. A cardboard box, for instance, may contain fibres that are on their first recycle and final recycle.”

Sign-up and receive the Business Media MAGS newsletter OR SA Mining newsletter straight to your inbox.

Sign-up and receive the Business Media MAGS newsletter OR SA Mining newsletter straight to your inbox.