SA Mining

Realigned AECI Reaps The Rewards

By Nelendhre Moodley

Benjamin Franklin, one of the founding fathers of the United States, said, “If you fail to plan, you are planning to fail.” This adage holds true for many businesses and situations; and a forward-thinking strategy has often helped firms sail over ruinous hurdles.

The COVID-19 pandemic has been one such hurdle that has seen a number of businesses fold. However, for the Mining Division of the South African listed AECI Group, AECI Mining Explosives, which in 2018 initiated its Project Realign to ensure business well-being, the move has proved to be well timed and propitious.

“Years ago we anticipated that the local market would be facing some pressures and decided that the AECI Mining Explosives business needed to be realigned to cope with the impending pressures. One of the key focus areas was to ensure that our cost structures were correct to withstand the projected challenges.

“We undertook Project Realign to ensure growth and a business that could thrive well into the future. In fact, these measures initiated prior to the onset of COVID-19 have helped us to more than adequately forebear the pandemic,” AECI Mining Explosives MD Edwin Ludick tells SA Mining in an exclusive interview.

The implementation of Project Realign has seen AECI Mining Explosives overshoot its target of a R200-million savings last year. Looking ahead, the company will continue to implement identified cost-saving measures, says Ludick.

African strategy

On the back of strong commodity prices, South African and African economies have been boosted, adding to state coffers and aiding mines to reinvest in greater exploration spend. Over the recent past, local commodities producers, and gold and PGM miners in particular, have delivered some sterling results, with many reinvesting to expand and grow their business.

Further to this, the Department of Mineral Resources and Energy’s Gwede Mantashe and the Minerals Council South Africa are targeting a larger slice of the global exploration spend. In fact, the sector is eyeing ways to garner up to 5% or $500m of the global spend in the next few years. For the South African listed explosives company this is an assurance of a strong and sustainable mining project pipeline going forward.

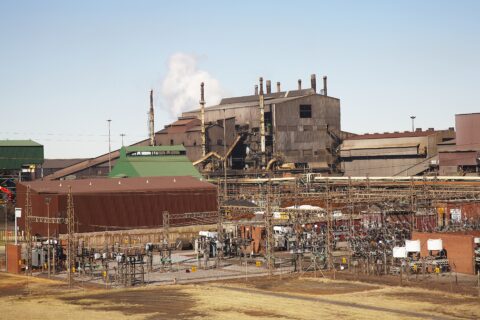

For AECI Mining Explosives, who has been leading the explosives industry since 1896 when gold was discovered in Johannesburg, this is important for its key growth market – Africa. Although the company has over the years focused on product development to keep at the cutting edge of the explosives business and geographical expansion, moving beyond the continent to grow the business in Australia, Indonesia and South America, among others, Africa remains a key contributor to revenue.

“Our roots are in Africa and we see growth in Africa as still very relevant to our strategy. We will continue to help mining houses mine safely and cost-effectively in all the African territories in which we operate,” says Ludick.

AECI Mining Explosives already has a strong and well-established presence in all key mining destinations in Africa, including Zambia, Zimbabwe, Botswana and the Democratic Republic of the Congo.

Their African growth strategy is premised on the hub and spoke methodology which effectively relies on establishing a presence in a strategic location and then growing the business by supplying product into neighbouring areas.

“We prefer to manufacture locally in the identified country and employ local people. In this way we are able to support rural communities through job creation and growth opportunities.”

And while Africa is considered to be a mature mining market, constant exploration in the region will continue to unlock new opportunities, including those aligned to future technological advancements such as battery metals.

Interestingly, an increasing number of African governments, including those of Botswana and Angola, are rolling out geological mapping programmes to identify new areas of mineral opportunities.

AECI Mining Explosives’ strong data-sourcing strategy, which includes attending key events like the Africa Down Under conference and keenly following the progress of new mining projects and tracking the progress of emerging miners, ensures that it is able to keep track of all new projects as they are rolled out.

“Attending such events and touching base with mining houses ensures that we are able to make contact with the relevant projects early on and thus provide our expertise from both the mining chemical and explosives segments of the business.”

New product developments

The well-established surface and underground explosives specialist invests heavily on research and development (R&D) which guarantees that it remains at the forefront of a highly competitive business segment.

“We are in the process of making big strides towards digitisation and digitalisation of most of our activities both in the back-end (automation and AI) and front-end, like smart trucks and triangulation of blast positions with DGPS (Differential Global Positioning System) to support mine managers with hands-on information, optimal blast performance and the best quality product,” explains Ludick.

Their drive to identify solutions to the explosives-related challenges that clients face has seen the explosives manufacturer develop the world’s deepest emulsion vertical drop system – a massive game changer for the global mining industry.

“With mines focused on improving safety and driving down costs, the vertical drop system has garnered great interest from mines across the world (Europe, South America and Australia) as well as locally in Africa.”

Recently, Non-Ferrous China Africa (NFCA), which is busy with an expansion project on its Chambishi mine in Zambia, opted to install AECI Mining Explosives’ emulsion vertical delivery system (EVDS) as part of its aim to develop a cost-effective mining operation.

The system delivered both the emulsion and sensitiser at depths of up to 980m directly to a storage facility underground. According to NFCA, the key benefits it has realised include improved safety; seamless inventory control; reduced interface with explosives; optimised ordering, delivery and charging units refilling; reduced maintenance, fuel and asset wear; and reduced risk of theft. Other gains include reduced time and labour resources.

In another recent development, the explosives manufacturer launched a significantly enhanced version of its bulk emulsion explosives – dubbed Powergel X² – a product that is suitable for extreme blasting conditions. Powergel X² is designed for surface mining applications where extreme blasting conditions such as hot blast holes and reactive ground, or a combination of both, exist.

“Minerals will always be needed and used and mining will always be a part of this process, which means that we will be here to partner with our customers in providing them with the best advice and technology,” says Ludick.

Sign-up and receive the Business Media MAGS newsletter OR SA Mining newsletter straight to your inbox.

Sign-up and receive the Business Media MAGS newsletter OR SA Mining newsletter straight to your inbox.