SA Mining

KELLER Eyes New Markets

By: Nelendhre Moodley.

Pressure-sensing specialist KELLER, founded in 1974, is looking to establish a firm footing in the Southern African market, CEO of KELLER Netherlands, Belgium and South Africa, Martijn Smit, tells SA Mining.

While the company has delivered on a few projects on the continent, its presence in Southern Africa is minimal. As such, the company is eyeing Africa as its next significant growth node.

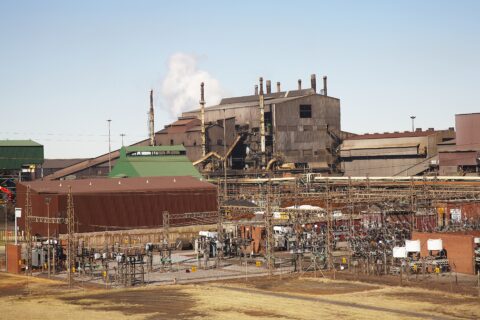

“The Southern African market is important. We believe this market has a lot of potential as KELLER is a globally strong market player in industries such as mining (dewatering and hydraulic pressure sensors for trucks and machinery), tank contents and water (level and loss) measurements,” explains Smit, who has been tasked to establish a presence in Southern Africa.

However, KELLER’s expansion plans, which were scheduled to be rolled out last year, were hampered by the onset of the COVID-19 pandemic.

“Our expansion drive has been delayed by a year now due to Covid-19. Importantly, this delay has prevented me from travelling to South Africa to gain a better understanding of market opportunities and to put in place a suitable market strategy.”

Meanwhile, the recent emergence of the new, more transmissible coronavirus variant, known as N501, has seen many countries placing travel bans on South Africa.

Aside from travel restrictions, the pandemic has severely disrupted important industry events, such as exhibitions. Every year, KELLER AG presents its products at leading trade fairs for sensor systems and measurement technology all over the world.

With these great lead-generating opportunities taken away, KELLER has opted to generate leads by focusing on developing personal contacts, including those with Instrotech, in the hope of gaining insight on new projects being rolled out and ultimately increasing its turnover.

The company is also relying heavily on its media presence (offline and online) to help target new areas, clientele and projects.

“The plan is first to expand the awareness of the KELLER brand through editorials and advertising. This is being done together with our representative, Instrotech, in Johannesburg.

“In particular, we are highlighting KELLER’s specialist capabilities as an important manufacturer of high-quality but affordable pressure and level sensors and our focus on new technologies like wireless readout through a cloud portal. KELLER’s products are manufactured at our facilities in Switzerland to ensure that product quality is to the highest standard possible.”

The company manufactures and sells more than 1.2 million pressure-measuring cells every year.

Growing KELLER’s Southern African footprint

According to Smit, KELLER has over the past decade supplied its products, including its pressure sensors, to a number of projects in Africa.

“One of these was a big project where our digital level sensors monitored the gasoil stock for electricity generators at cellphone hubs. Another project worth mentioning is the pilot project we started last year in Kololo Game Reserve, near Vaalwater, in the Limpopo province, where we wirelessly monitor the stock of drinking water.

“Kololo is located in a rural area and although it is connected to the electricity network, the network is known to fail now and then so a diesel electricity generator is on standby.”

Discussing Kololo’s water system, Smit explains that it consists of three stages: a water well, eight accumulating tanks, and distribution of the water to the various sites, including the lodges and restaurant.

Kololo’s main water source is a well that goes to a depth of 100m. Measuring the level of water in the well is important as it helps to predict the stock of water. KELLER’s installed level measurement system provides the client with data related to fluid levels, and data history which can be used for insight into consumption and/or malfunctioning.

Access to this information can lead to great savings or prevention of unnecessary repairs and non-revenue problems.

“While this is not a big project, it does illustrate the potential of new technologies as a significant cost saver. In fact, the exact same technology can be applied to any fluid measurement – wine tanks, non-revenue water (water loss), as well as applications in dewatering mines.”

According to Smit, pressure sensors are important as they can also signal theft. “An unusual decrease of a tank level might indicate leakage or theft. The incorporation of a tank content measurement system [means one can] detect theft of gasoline, for example from electricity generators.

“When one tries to mask theft by refilling the tank with water, we have special sensors which measure the density of the fluid as well. As water is heavier than diesel, we can detect a change in density.

Sign-up and receive the Business Media MAGS newsletter OR SA Mining newsletter straight to your inbox.

Sign-up and receive the Business Media MAGS newsletter OR SA Mining newsletter straight to your inbox.