SA Mining

Hole In one?

In light of the changes to South African mining production and performance on main contributors to mining, Sandvik Mining and Rock Technology Southern Africa continues to seek new ways to lift production and lower costs by investing heavily in research and development. This means it can deliver products and equipment that meet and exceed the sector’s needs, Sandvik’s business line manager surface drills and exploration Rumisha Motilal tells SA Mining.

On the back of industry’s demand for technologically advanced “intelligent” equipment, equipment manufacturer Sandvik Mining and Rock Technology recently unveiled its first intelligent down-the-hole surface drill rig called the Leopard DI650i. It is a diesel-powered, self-contained crawler mounted drilling rig designed for DTH blasthole drilling in the mining, quarry and construction industries. The drill is equipped with an operator’s cabin, fixed boom, dry dust collector and drill pipe changer and incorporates state-of-the-art design and layout.

“Sandvik is extremely excited to introduce the first intelligent machine within the 115mm-to-203mm range of down-the-hole surface drill equipment to industry,” says Motilal. The machine delivers a number of benefits such as improved productivity, efficiency and safety as well as reduced costs and, apart from being equipped with intelligent fuel-saving features which make the new DI650i up to 15% more fuel-efficient than the traditional DTH-drill rig, this automated product is easy to use.

The product has been developed at Sandvik’s Finland Tampere branch, which produces all Sandvik’s top hammer drill rigs – including the DPi1500 range, a market leader in terms of Top Hammer drills, Ranger DX800, DX900 and the Leopard DI550.

“We have conducted trials in Europe where the DI650i has exceeded the benchmark criteria against the competition. Therefore, we are excited to see how this machine will perform onsite with Aveng Moolmans, one of the largest surface mining contractors in Africa.”

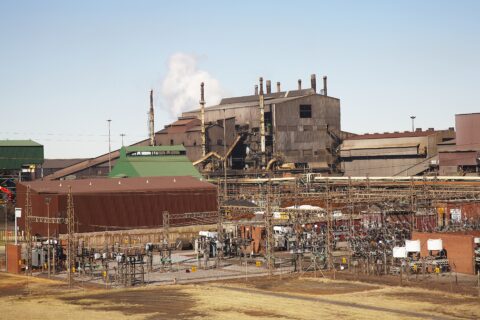

Sandvik collaborated closely with Aveng Moolmans to produce this intelligent drill. “Given the strong relationship between Aveng Moolmans and Sandvik, which spans over 20 years, they were keen to partner with us as we embraced the latest technology journey. Following product development, Aveng Moolmans purchased the first DI650i drill rig for use at its Gamsberg operation in the Northern Cape.

The DI650i was initially launched at Electra Mining, Africa’s premier mining and construction equipment event which showcases the latest cutting-edge innovations and technologies in machinery, equipment, products, consumables, services and solutions. Now the machine will be showcased “to Sandvik’s customers at a road show in Kathu, Northern Cape”.

Is Africa ready for a smart drill rig?

While customers are eager to acquire the latest autonomous drill rig, are they actually set up and ready for it? In Motilal’s opinion, many mines are embracing technology. “It is good to note that the Leopard DI650i has scalable automation, which means that clients can customise it to meet their immediate needs and expand existing equipment capability with additional functionality as the need arises. Various automation features can be retrofitted as automation requirements change. As such, clients have the option to retrofit additional features such as Automine® Surface Drilling onto their machines.”

Operators have taken well to Sandvik’s drilling product range and “once they become accustomed to using the product, it becomes their equipment of choice”.

“As all Sandvik’s automation platforms have a similar set-up, operating different pieces of equipment in the range is seamless which makes training operators on newer equipment easy,”

explains Motilal.

Drilling to perfection

According to Motilal, the intelligent drill rig with full-cycle one-hole drilling automatics can drill to a depth of 53m. It can be equipped with a wireless data transfer option that offers the possibility to download and transfer drill patterns from the mine to the machine and back. Alternatively, the information can be extracted and saved onto a USB.

“This offers the client a platform to access information from various locations in real time, which assists with ensuring accuracy as related to size, depth and drill hole interval. Editing tools also make it possible to design each hole individually. In essence, a client can, with just a click of a button, accurately drill as per requirement.”

Further benefits of the drill rig include a comfortable cab, which comes standard with reduced cabin noise levels, improved safety features as well as good aftermarket support and back-up services. The new-generation machine is appealing to experienced operators and youngsters accustomed to the use of joysticks as used on video game consoles.

“The introduction of the intelligent Leopard DI650i makes for an exciting workday,” states Motilal.

Sign-up and receive the Business Media MAGS newsletter OR SA Mining newsletter straight to your inbox.

Sign-up and receive the Business Media MAGS newsletter OR SA Mining newsletter straight to your inbox.