SA Mining PR

Suited For All Conditions

“Victaulic products are tested to accommodate not only seismic, but thermal movement as well,” states Marcel Ley, Regional Manager Victaulic South Africa. “This testing allows for system durability in practically all conditions, ensuring that engineers truly see the benefits of making use of our industry-leading products.”

Accommodating seismic movement

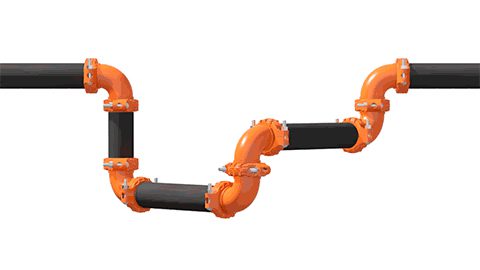

The main approach to designing a piping system that accommodates seismic activity is to an engineered combination of both rigid couplings and flexible couplings in key areas of the system to accommodate movement and sway. According to Ley, typically more than 95 percent of the grooved couplings used in a piping system will be rigid, while the remainder will be flexible couplings.

“The importance of this lies in the fact that too much swing could affect other pipes and equipment, despite being within the capability  of the grooved coupling. The key to effectively accommodating movement in a building is to allow controlled movement, and that can be done with flexible grooved technology.”

of the grooved coupling. The key to effectively accommodating movement in a building is to allow controlled movement, and that can be done with flexible grooved technology.”

Ley further explains that two basic grooved coupling styles can be found. These include flexible grooved couplings which allow for a restrained amount of angular and axial movement; and the other being rigid grooved couplings which do not allow for movement and can be used in instances where immobility in the pipe joint is needed, and can be described as similar to that of a flanged or welded joint.

To test the superiority of Victaulic flexible couplings in accommodating seismic movements, the couplings were tested at the ATLSS centre, a member of the nationally recognised NEES (Network for Earthquake Engineering Simulations) testing group. Victaulic couplings ranging in size from 4″-16″ (100mm – 400mm) were exposed to accelerations up to 50% greater than the Northridge, California earthquake which measured a staggering 6.7Mw magnitude.

The water-filled assemblies were pressurised to 200psi/1375kPa for the duration of each test; no pressure loss or leakage was noted.

“The technology is most notably in use at the Burj Khailfa in Dubai. As the tallest building in the world, the structure required an innovative, flexible solution to accommodate structural shrinkage as well as movement and sway due to wind load,” explains Ley.

“As such, Victaulic Flexible Couplings were used to absorb system movements from building settlement and wind sway; while Victaulic Style 155 Expansion Joints, used as flexible connectors, were installed at strategic locations on potable water and wet risers.”

Accommodating thermal movement

“Some of the most damaging affects to a piping system can be the result of not accommodating for movement,” comments Ley. “Temperature changes can exert dangerous and damaging reactive forces on pipe components and equipment.”

There are however measures to accommodate pipe movement in instances of thermal change; with the company having identified key advantages in making use of its innovative products. These include pipe design flexibility; a reduction in pipe system stress; a more compact and productive method of installation as opposed to welding; and finally the conformity to industry practises.

The key to effectively accommodating thermal expansion and contraction in a piping system is to allow the predictable, controlled movement of the piping itself. This can be achieved in a variety of ways; the selection of a specific method is based upon the engineer, the type of piping system and the project parameters. Further, Victaulic considers a number of key factors in which grooved coupling can accommodate thermal movement. Firstly, grooved couplings provide an expansion joint by using grooved mechanical pipe components, which essentially allow the system to “free-float”. Additionally, they utilise the linear movement or deflection capabilities of flexible grooved couplings, as well as providing an expansion loop by making use of the grooved mechanical components.

“We at Victaulic believe that grooved couplings are a smart alternative to conventional methods. Not only are they easier and faster to install over welding, but they accommodate movement within the design capabilities of the grooved coupling,” describes Ley.

“By allowing for thermal movement within the pipe join itself, piping systems can be installed in smaller spaces. The inherent flexibility of the pipe joint ultimately lowers stress on the various components in the system.”

Noise and vibration attenuation

Mechanical room equipment creates noise and vibration in a piping system, which can be difficult to contain. Designers can specify the use of Victaulic couplings to isolate this vibration.

“Victaulic flexible couplings will also accommodate for misalignment, reduce stress on pumps and equipment connections, and accommodate linear movement and angular deflection in a piping system.”

“The unique construction of our grooved coupling enables the gasket to seal against pipe, while the housing provides both space for the seal to flex and containment to prevent overstretching. Our couplings work to create a permanent leak-tight seal, with no need for additional reinforcement. Additionally, ductile iron also absorbs sound,” concludes Ley.

Victaulic completed testing at NASA’s Vibration and Acoustic Test Facility (VATF). The results showed that the vibration attenuation provided by three Victaulic flexible couplings installed near the source of vibration outperformed conventional double sphere rubber connectors and stainless steel braided pump connectors.

Sign-up and receive the Business Media MAGS newsletter OR SA Mining newsletter straight to your inbox.

Sign-up and receive the Business Media MAGS newsletter OR SA Mining newsletter straight to your inbox.