SA Mining PR

See Better To Work Safely

Gone are the days of relying only on cap lamps and low intensity stationary lighting solutions! What if there is a solution that will intensify lighting in pitch dark hazardous areas, and convert it to daylight?

With its vast experience in underground mining, QualiRock took the leap to design and develop the SafeLight to help a multitude of industries. The SafeLight takes intrinsically safe, ambient lighting to the areas where it is needed most, and where life-threatening explosions are a continuous risk.

The SafeLight is a revolutionary invention that is set to light up not only the mining industry but a broad spectrum of industries that rely on lighting to get the job done safely.

QualiRock’s SafeLight was designed initially for underground mining conditions as an in-stope lighting device where spot lighting simply does not make the grade.

This innovative and proudly South African product will light up the dark places and take away the guesswork from every worker in hazardous workplaces. The SafeLight redefines light and supersedes the direct light of a cap lamp.

The question is: “What makes this innovation any different from what is used?” Chief Executive Officer, Pierre Cronjé of QualiRock – holding company of the patented SafeLight product, answers: “As a practicing Rock Engineer doing assessments and fall of ground inspections, proper lighting is essential to see properly. I have always relied on a cap lamp and have often identified non-conformance issues caused by underground workers, only to realise that inadequate lighting is a huge contributing factor.”

“Then, Anglo-American approached QualiRock to incorporate a light source, into the Lekoba stick for safety during entry examination. We were required to come up with a better solution. Now I can take the SafeLight with me and it suddenly opens the underground world.”

“After many hours of brainstorming, two years of planning and strategizing, the “SafeLight” was born or saw the light, with more modern concepts of Mark II and Mark III already in a design stage”, Cronje proudly attests.

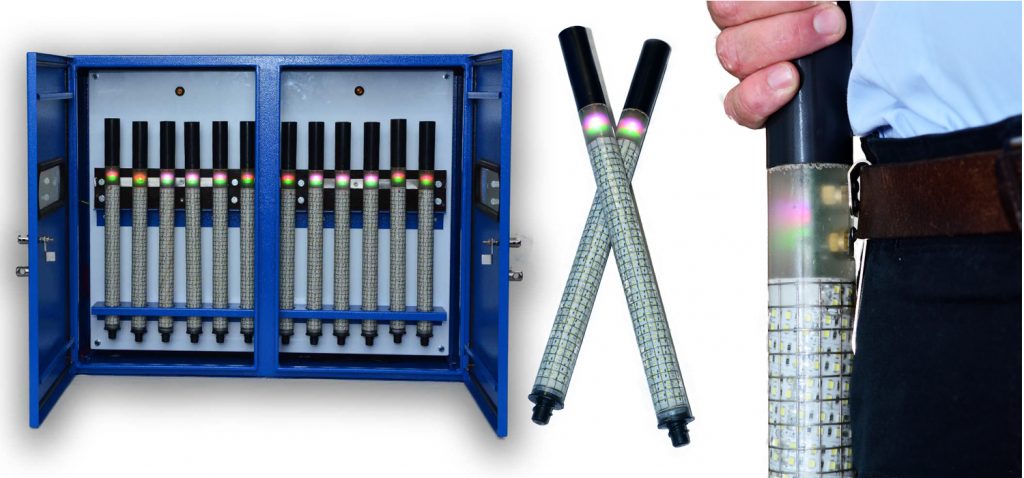

The specifications and benefits of the SafeLight do make it sound like the magic lighting wand the industry has been waiting for. It is anti-static, robust, and intrinsically safe. A magnetic end cap lends itself to being fixed to any metal structure/object, such as installed roof support units.

With its 360-degree lighting capability, it can provide continuous lighting for up to eight hours before recharging is required. The SafeLight is wireless and no cables is needed when the light is used.

“Every rescue bay underground should have these installed”, Cronje indicates, “and what’s more”, he adds, “they are safe to use underwater as well”.

To conserve battery power, a switch handle is fitted to the SafeLight to quickly “twist” off the light when not needed. For convenience, the belt clip on the SafeLight also acts as a charging port when charged in the charging cabinet.

Certified and approved IP 65 charging cabinets can either host six or twelve lights at a time and can be ordered based on the configuration needed.

With its official intrinsically safe certification and approval, the SafeLight can be used in other industries such as the Petrochemical industry, with chemical storage facility and tanker inspections, and any other industry where low-light conditions occur. In the end, it is about safety and providing enhanced lighting from a reliable DC source so workers can work safely in these hazardous, difficult and most often remote areas.

With several units already installed at mines within South Africa, the QualiRock team is working around the clock to increase production to meet the growing demand for the SafeLight.

As Cronje says, “you cannot mine safe, if you don’t SafeLight your way”, the SafeLight facilitates better visibility, which in turn provides safer working conditions.

For further information, contact:

Pierre Cronjé

QualiRock

Tel: +27 13 932 5110

Mobile : +27 82 823 6705

Email: pierre@bigcr.co.za.

Sign-up and receive the Business Media MAGS newsletter OR SA Mining newsletter straight to your inbox.

Sign-up and receive the Business Media MAGS newsletter OR SA Mining newsletter straight to your inbox.