SA Mining

Need For Speed

By: Nelendhre Moodley

The COVID-19 pandemic continues to wreak havoc across the globe, tracking just over half a million deaths to date. A fragile world economy characterised by a soaring number of companies falling prey to the pandemic and an unprecedented unemployment tally best describe the current situation. In a bid to better understand the impact of the pandemic and lockdown on equipment manufacturers, which by this time has shifted gears to Level 3, SA Mining caught up with conveyor belt cleaning equipment manufacturer Brelko’s MD Kenny Padayachee.

The five-week Level 5 lockdown took a hefty toll on business, with many firms not expected to survive the shutdown, says the Johannesburg-based equipment supplier. While Brelko was awarded an essential services certificate, which ensured that the business remained operational at a basic level, Padayachee says the closure of export hubs (ports and airports) effectively put a stop to a major portion of its business.

Added to this was the implementation of force majeure on contractors by mining majors essentially “suspending on-site contracts”, and requiring contractors to immediately remove their equipment and presence from clients’ operations.

“Although we were able to prove that we are part of essential services, the suppliers and sub-suppliers in our value chain were on shutdown. To ensure that Brelko remained operational, we had to encourage our suppliers to apply for essential services permits to operate under Level 5 lockdown. Associated suppliers included equipment powder coaters, profilers and urethane producers.”

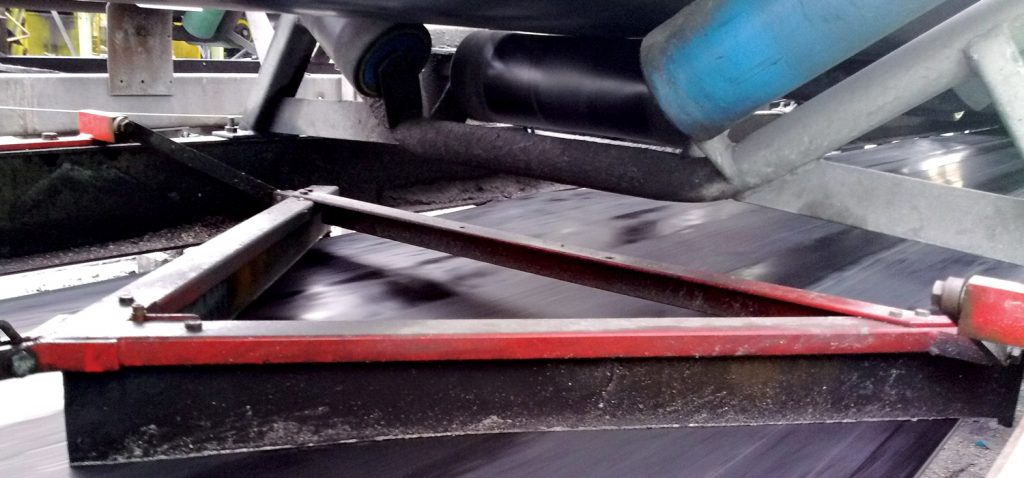

Brelko is an equipment supplier to South Africa’s key industries, including to petrochemicals giant Sasol, power utility Eskom and coal and heavy minerals mining company Exxaro’s Grootegeluk mine in Limpopo. “We service all our conveyor cleaning equipment at these sites – a vital service offering to ensure that processes operate smoothly, without equipment failure to cause disruptions.”

Aside from an April turnover that was significantly “down”, Padayachee explains that the COVID-19 pandemic has brought with it an added burden of costs.

Following the pandemic-related regulations associated with health and safety in the workplace, companies have had to outline and follow through on measured risk assessment plans, which aim at mitigating on-site risks.

“By law companies are required to adopt high levels of health and safety measures, including providing hand sanitisers and monitoring employee temperatures to ensure that they are COVID-19-free, as well as supplying three face masks to each workshop employee and new masks every day to employees servicing equipment on-site. While the face masks are relatively cheap, following the onset of the pandemic, they have tripled in price,” says Padayachee.

Apart from pandemic-related health and safety costs adding a further 10% to 12% to company costs, currency fluctuations have been wreaking havoc on businesses that were in the process of inking equipment deals with European manufacturers at the onset of the pandemic, he says.

Brelko was in the process of purchasing equipment from Italy aimed at improving productivity just as COVID-19 was unfolding, and was subsequently caught on the back foot following the erratic rand-dollar exchange rate, which effectively jumped from $16 to the rand to $19 to the rand within days.

“As the order required an immediate 60% down-payment, the exchange rate had a massive negative impact on the price of the equipment we were ordering.”

Marketing strategy

Even as the lockdown eases, the way business is conducted has forever changed, with major conferences such as Mining Indabas set to alter format.

A key event on the calendar for equipment manufacturers to the mining and construction industry – the Electra Mining exhibition – has been cancelled.

This has left companies including Brelko, which showcase their latest innovative technologies at the event, to figure out new marketing strategies, Padayachee says.

“Fortunately Brelko has been proactive and uploaded key product information, such as detailed installation and maintenance, onto flash drives.”

Since adopting this decision a decade ago the equipment manufacturer has translated its catalogue information into various languages, including English, French, Spanish, Portuguese, Arabic and Russian.

Brelko products are sold across the globe – in Europe, the United States and Asian countries, including Arabic-speaking countries.

Investing in innovation and technology

In line with keeping “ahead of the curve”, the niche market equipment manufacturer is investing in the acquisition of key equipment aimed at improving efficiency, accuracy and productivity, such as a fully automated spray boot, ordered from Italy before the lockdown. This was ordered from Trendline Automotive Suppliers, valued at R2.9-million.

“We take automation and innovation seriously because our objective is to produce consistent and accurately manufactured products. Given that some of our metal parts are powder-coated, sandblasted and spray-painted, we were looking for quick-drying solutions. The acquisition of a double spray booth measuring 14m, with one section earmarked for paint preparation, mixture and spray, while the other section is allocated for quick dry, means that Brelko products will have a car-like paint finish.

“Our aim is to be the very best at what we do, so precision and accuracy are paramount,” says Padayachee.

In anticipation of the spray booth scheduled for arrival in October, the company has been preparing the floor, the bay area and power supply installation.

In addition, Brelko has invested in the acquisition of a specially designed robotic gluing system from Directech, valued at R4.7m.

“Given the time-consuming and laborious process associated with gluing belt scraper components, the robotic gluing system will, aside from saving on time and cost, deliver accurately glued components.”

In terms of the value that the machine will add to Brelko, Padayachee says it will eliminate the hidden costs associated with inconsistencies related to manual production and thus result in fewer product returns.

To ensure that employees are well equipped to handle the hi-tech cutting-edge robotic gluing system, Brelko will upskill four employees to meet the new equipment requirements.

While ordinarily automation is associated with a reduced labour force, Padayachee says that as the company is looking to expand its local manufacturing offering, it will not be retrenching personnel.

“At the moment Brelko is outsourcing some of its production to local suppliers and the new investments will allow us to increase in-house capacity.”

Further to this, the company recently acquired a $240 000 fully automatic polyurethane dispenser able to produce 12 tonnes a month. Acquired in February, the dispenser will help the company triple the number of moulds currently produced.

Sign-up and receive the Business Media MAGS newsletter OR SA Mining newsletter straight to your inbox.

Sign-up and receive the Business Media MAGS newsletter OR SA Mining newsletter straight to your inbox.